ProPOV Capstone Day 2

17 May 2011

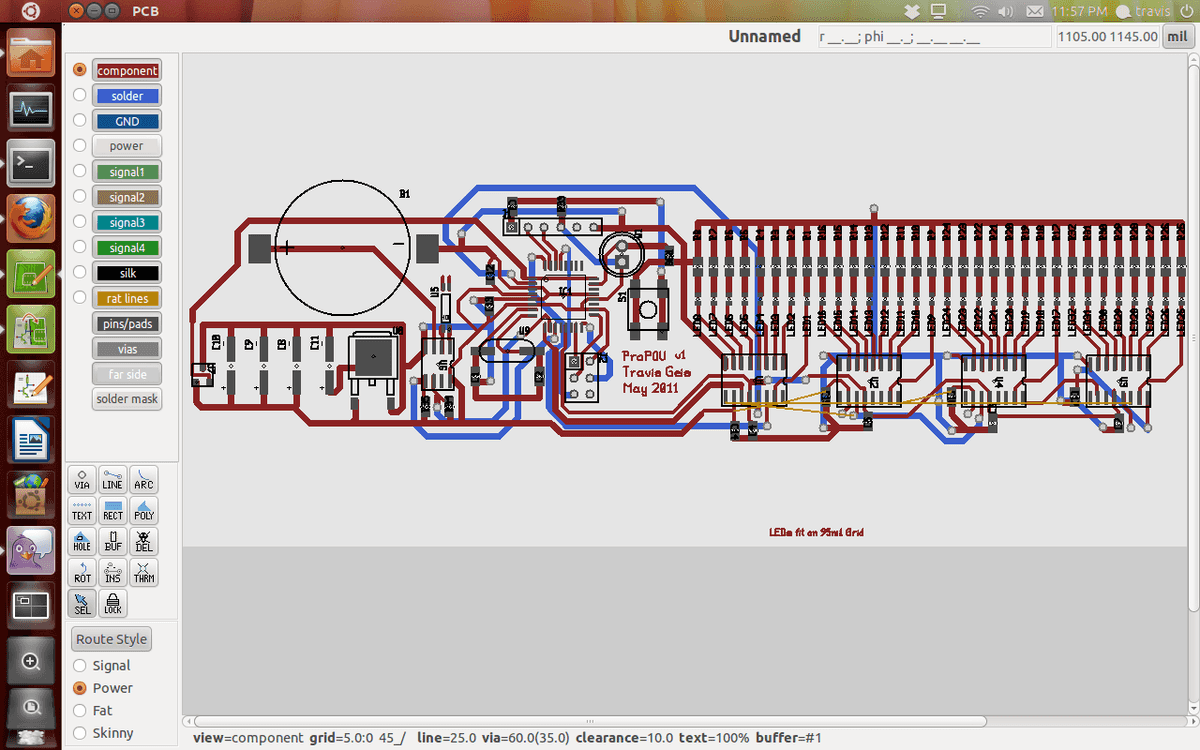

Today I worked mainly on the PCB for the ProPOV.

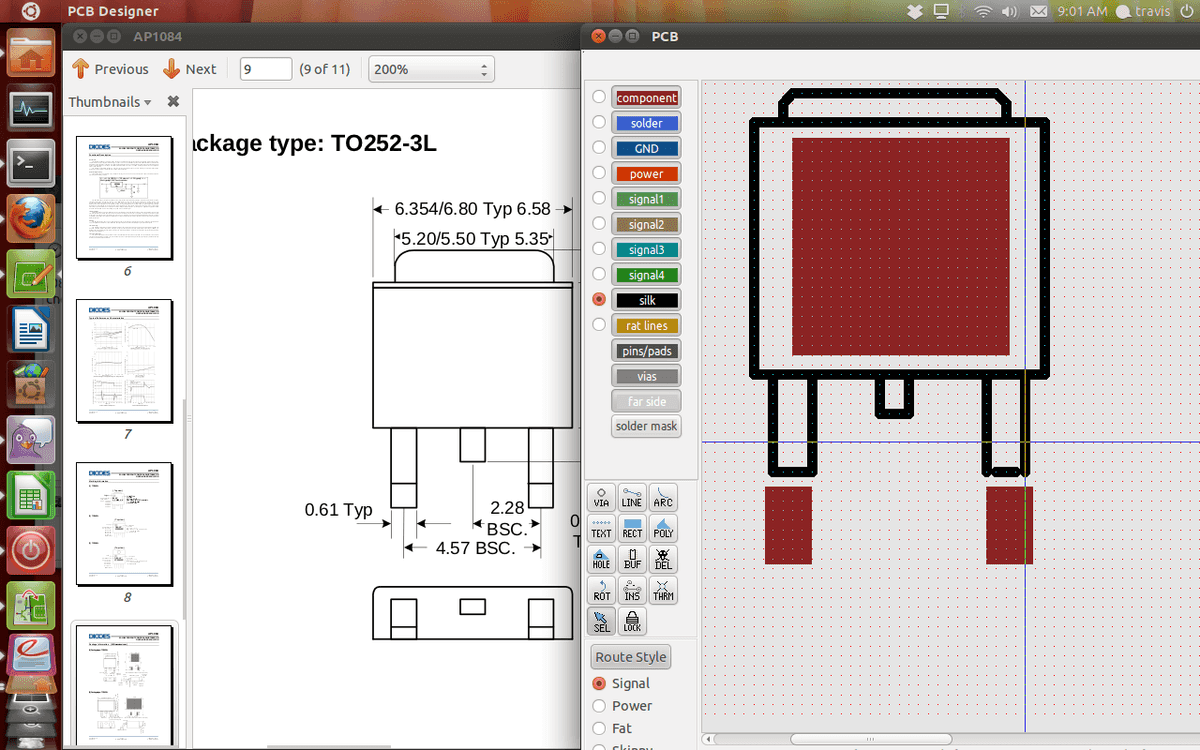

A lot of the initial PCB work is creating custom footprints for the components I’m using. I do this directly in gEDA PCB, which allows simple primitive geometry (curves, rectangles, lines, vias).

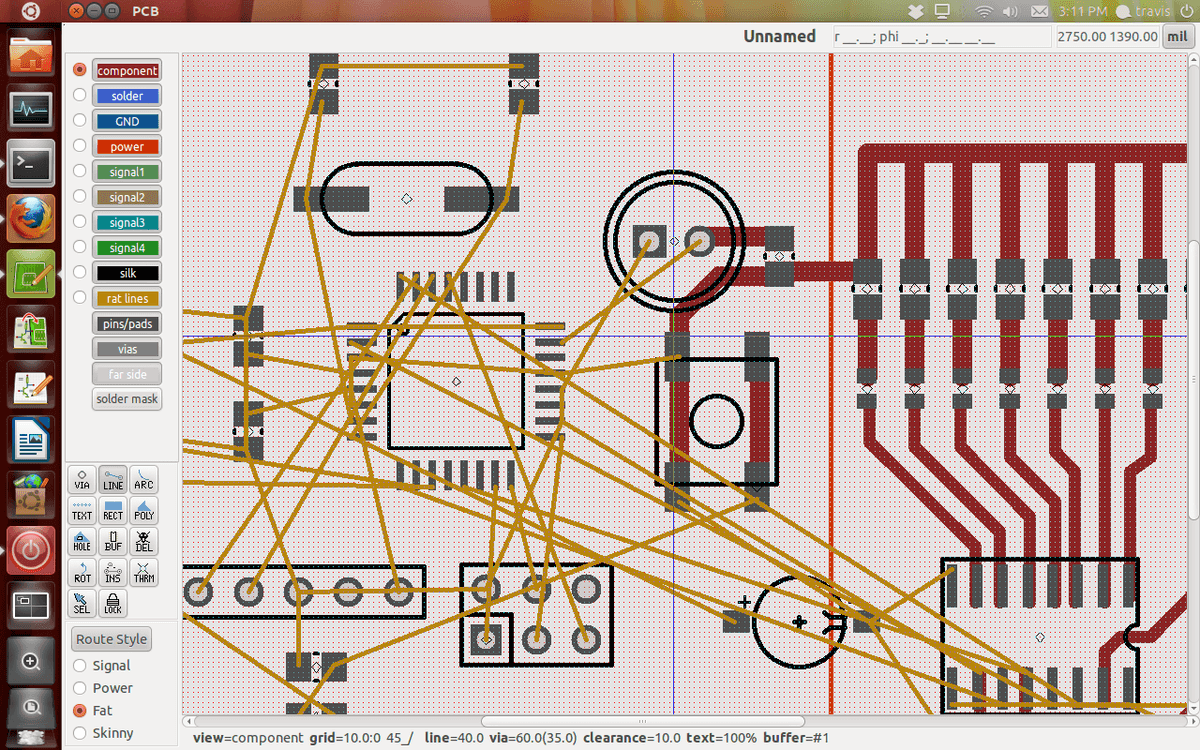

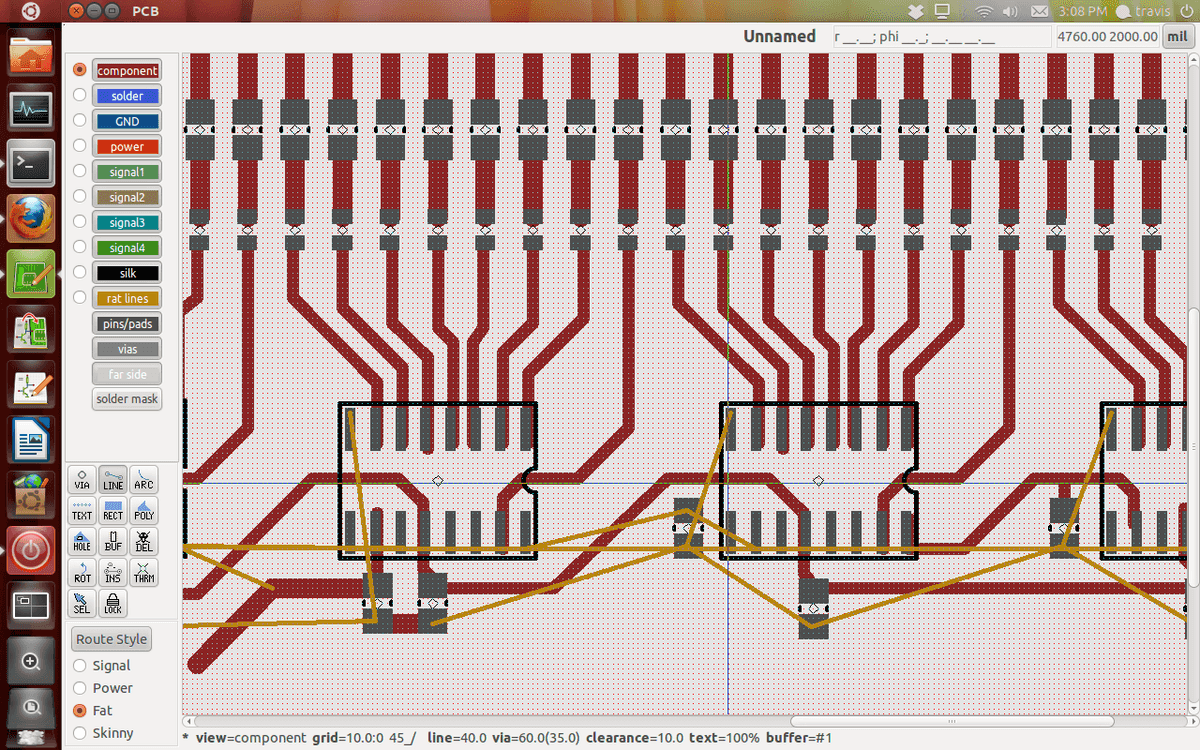

Routing the LED branch of the circuit is fairly simple, because each shift register has most of its outputs on one side and the LEDs can just line up and plug in. The CPU area, though, has a mess of tangled crossovers called “rat lines” that need to be sorted out.

The PCB uses a copper-clad board from radio shack, 6.125” by 4.5”. These are the maximum dimensions of the rotor.